On the other hand, a product with a low gross profit may actually be very profitable, if it uses only a minimal amount of administrative and selling expense. Analyzing overhead costs in service-based organizations is essential for understanding the https://www.bookstime.com/ total cost of providing services or performing functions. By considering different perspectives, utilizing cost allocation methods, and conducting in-depth analysis, organizations can make informed decisions to optimize their operations and improve profitability. Non-Manufacturing Costing plays a crucial role in measuring the total cost of providing a service or performing a function.

- Costs that are not related to the production of goods are called nonmanufacturing costs23; they are also referred to as period costs.

- These minor types of materials, often called supplies or indirect materials, are included in manufacturing overhead, which we define later.

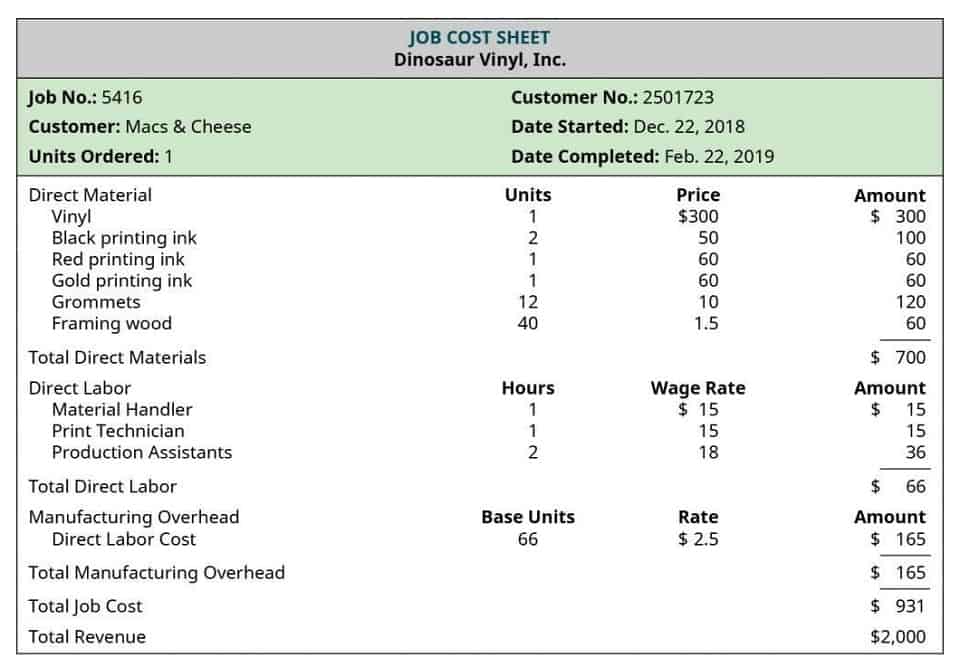

- Product costs are assigned to an inventory account on the balance sheet, initially.

- Sometimes it is difficult to discern between manufacturing and non-manufacturing costs.

- The sum of direct labor cost and manufacturing overhead cost is known as conversion cost.

- As we indicated earlier, nonmanufacturing costs are also called period costs; that is because they are expensed on the income statement in the time period in which they are incurred.

Nonmanufacturing Overhead Costs

- All manufacturing costs that are easily traceable to a product are classified as either direct materials or direct labor.

- The resulting unit costs are used for inventory valuation and for the calculation of the cost of goods sold.

- This is why the manufacturing costs are often termed as product costs and non-manufacturing costs are often termed as period costs.

- Each of them requires a different set of cost control measures, making appropriate cost categorization even more essential.

- For instance, are the salaries of accountants who manage factory payrolls considered manufacturing or non-manufacturing expenses?

- If the net realizable value of the inventory is less than the actual cost of the inventory, it is often necessary to reduce the inventory amount.

Since nonmanufacturing overhead costs are outside of the manufacturing function, these nonmanufacturing costs are immediately expensed in the accounting period in which nonmanufacturing costs they are incurred. That is why accountants refer to nonmanufacturing costs as period costs or period expenses. These costs are reported on a company’s income statement below the cost of goods sold, and are usually charged to expense as incurred.

Examples of Nonmanufacturing Overhead Costs

These costs aren’t directly related to the physical production of their devices but are essential to running the business and its long-term growth. Examples of direct materials for each boat include the hull, engine, transmission, carpet, gauges, seats, windshield, and swim platform. Examples of indirect materials (part of manufacturing overhead) include glue, paint, and screws. Direct labor includes the production workers who assemble the boats and test them before they are shipped out. Indirect labor (part of manufacturing overhead) includes the production supervisors who oversee production for several different boats and product lines. Non-manufacturing costs include those costs that are not incurred in the production process but are incurred for other business activities of the entity.

Non-Manufacturing Overhead Costs

Costs that are not related to the production of goods are called nonmanufacturing costs23; they are also referred to as period costs. These costs have two components— selling costs and general and administrative costs —which are described next. Costs that are not related to the production of goods are called nonmanufacturing costs23; they are also referred to as period costs24.

In addition to these techniques, service industries can also employ cost benchmarking, which involves comparing their costs to industry standards or best practices. This allows organizations to identify areas of improvement and optimize their cost structures. “Business in Action 2.5” details the materials, labor, and manufacturing overhead at a company that has been producing boats since 1968. Note 1.43 “Business in Action 1.5” details the payroll materials, labor, and manufacturing overhead at a company that has been producing boats since 1968. Note “Business in Action 2.3.1” details the materials, labor, and manufacturing overhead at a company that has been producing boats since 1968.

Manufacturing costs initially form part of product inventory and are expensed out as cost of goods sold only when the inventory is sold out. Non-manufacturing costs, on the other hand, never get included in inventory rather are expensed out immediately as incurred. This is why the manufacturing costs are often termed as product costs and non-manufacturing costs are often termed as period costs. These costs are not directly tied to the production of goods or services, but rather to the overall operation of the company. Examples of period costs may include rent, salaries and wages of administrative staff, office supplies, marketing and advertising expenses, and other similar expenses. While these costs are necessary for the overall functioning of the business, they do not directly contribute to the production of goods or services.